The Center for Drug Evaluation (CDE) has issued the “Technical Requirements for Pilot Registration and Application of Phased Manufacturing of Antibody Drug Conjugates (ADC).” This document complements the “Pilot Work Plan for Phased Manufacturing of Biological Products” released last month and aims to guide the pilot work of phased manufacturing for ADCs, including small molecules, stock solutions, or formulations.

ADC Production and Quality Control

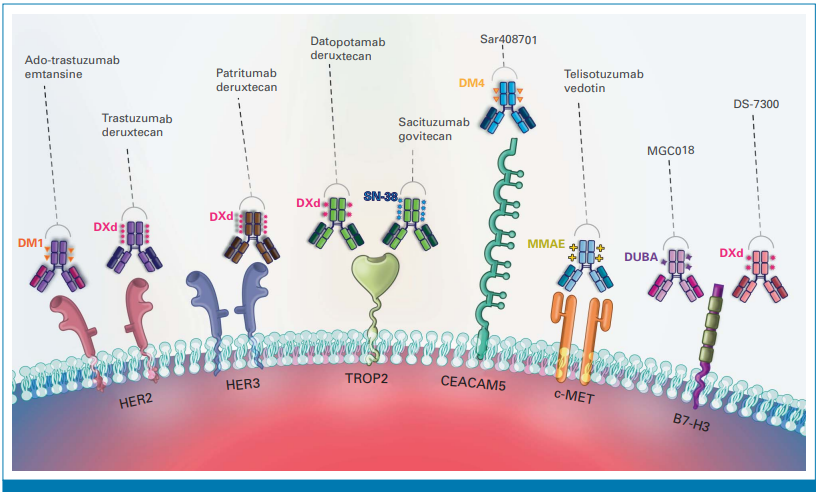

The document highlights that ADCs are produced by conjugating small molecules with conventional biological products, which introduces unique challenges in terms of structure, production, and other aspects. Due to the high volume of materials used in the ADC production process, there is a risk of introducing exogenous factors or toxic chemical materials, which necessitates a comprehensive quality control strategy based on risk assessment.

Quality Attributes and Lifecycle Research

The quality attributes of intermediate products, such as small molecules and raw materials, in the upstream production processes can impact the key quality attributes of subsequent processes or ADC raw materials/formulations. Therefore, it is essential to conduct research and verification across the entire production chain and lifecycle for phased manufacturing of ADC products.

Risks in ADC Phased Manufacturing

Compared to non-phased manufacturing, the phased manufacturing of ADCs may introduce new risks during the transportation and handover process of intermediate products. The applicant/marketing authorization holder (MAH) should focus on quality control, acceptance standards, and change research of intermediate products during transportation. Close attention must be paid to quality changes that may affect safety and effectiveness, such as protein polymer levels and payload detachment levels.-Fineline Info & Tech